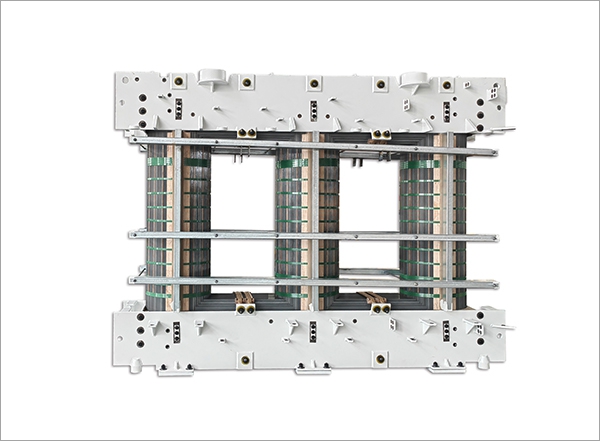

Power transformers are critical components in power generation and distribution systems, ensuring the efficient transfer of electrical energy between circuits. However, one of the most common and concerning issues with power transformers is vibration and noise, typically originating from the transformer core. These problems not only affect the operational environment and cause discomfort in nearby facilities but can also signal potential mechanical or magnetic issues that reduce the transformer’s lifespan. Understanding the sources of vibration and noise, as well as methods to minimize them, is essential for improving transformer performance, reliability, and acoustic comfort.

Transformer noise primarily originates from magnetostriction, a phenomenon in which ferromagnetic materials like silicon steel change shape when magnetized. During operation, alternating magnetic flux causes periodic expansion and contraction of the core laminations at twice the supply frequency (100 Hz or 120 Hz). This leads to mechanical vibrations, which, if not properly controlled, result in audible noise.

In addition to magnetostriction, several other factors contribute to transformer noise:

Understanding these sources is crucial before implementing any mitigation strategy.

One of the most effective ways to minimize transformer noise starts at the design stage, specifically with the selection of core materials and configuration.

Use of high-grade grain-oriented silicon steel (GO steel):

Modern transformers use cold-rolled, grain-oriented silicon steel with low magnetostriction properties. These materials have a preferred grain direction that aligns with the magnetic flux, reducing core deformation and vibration.

Amorphous metal cores:

Amorphous alloys have a disordered atomic structure, resulting in significantly lower magnetostriction and hysteresis losses compared to traditional laminated steel. Transformers with amorphous cores typically operate more quietly and efficiently.

Optimized core geometry:

Using a step-lap joint design at the corners of the core helps distribute magnetic flux evenly and reduces localized flux leakage, which minimizes both vibration and noise.

Proper lamination thickness:

Thinner laminations reduce eddy current losses and minimize the magnitude of mechanical forces between sheets, further reducing vibration amplitude.

Even with advanced materials, improper assembly can amplify vibration and noise. Therefore, careful mechanical design and precise assembly are essential.

Core clamping and tightening:

The core must be tightly clamped to prevent relative motion between laminations. The pressure should be uniform to avoid distortion, but not so excessive that it causes mechanical stress or magnetic deformation.

Use of resin bonding or varnish coating:

Applying special bonding agents or varnishes between laminations can prevent vibration and suppress noise. It also enhances insulation and prevents corrosion.

Avoiding air gaps:

Small air gaps in the core increase magnetic reluctance and cause localized flux leakage, resulting in additional vibration and noise. Ensuring a tight, gap-free assembly minimizes these effects.

Damping materials and pads:

Rubber or polymeric damping pads placed between the core and tank, or between mounting points, can absorb vibration energy and prevent its transmission to external structures.

Electrical and magnetic design also significantly influence transformer noise.

Flux density control:

Operating the transformer at a lower magnetic flux density reduces magnetostriction and thus lowers vibration amplitude. Although this may slightly reduce efficiency, it’s often a worthwhile trade-off for noise-sensitive installations.

Symmetrical magnetic flux paths:

Asymmetrical flux distribution can lead to uneven mechanical forces within the core. Using a symmetrical core design ensures balanced flux paths and minimizes vibration.

Minimizing harmonic distortion:

Non-sinusoidal voltage inputs or harmonics in the power supply can cause irregular flux variations, leading to unpredictable vibrations. Installing harmonic filters helps stabilize the magnetic field and reduce mechanical oscillations.

Beyond the transformer itself, the way it is installed and isolated from its surroundings plays a major role in reducing perceived noise levels.

Vibration isolators:

Transformers are often mounted on vibration isolation pads or springs that decouple the unit from the foundation. This prevents vibration from transferring into the floor or walls, where it can resonate and amplify sound.

Acoustic enclosures:

For transformers installed in noise-sensitive environments, such as hospitals or residential areas, acoustic barriers or soundproof enclosures can be used to contain noise.

Foundation design:

A solid, well-damped foundation minimizes resonance and prevents the amplification of low-frequency vibration. Concrete pads with embedded damping materials are commonly used.

Proper placement:

Locating the transformer away from reflective surfaces (such as walls or corners) reduces noise reflection and enhances acoustic performance.

Even the best-designed transformers can develop noise problems over time due to aging, loosening of parts, or material degradation. Regular maintenance is essential to sustain quiet operation.

Tightening checks:

Periodic inspection of core clamps and frame bolts ensures that mechanical tightness is maintained.

Oil and cooling system maintenance:

Keeping fans and pumps balanced and lubricated prevents additional noise from auxiliary equipment.

Thermal and vibration monitoring:

Advanced sensors can continuously track vibration levels, allowing early detection of issues like loose laminations or developing faults. Predictive maintenance based on these signals helps prevent major failures.

Cleaning and corrosion prevention:

Dust, rust, or insulation degradation can alter mechanical properties and increase vibration. Routine cleaning and protective coatings prolong stable operation.

Recent innovations in materials science and engineering are opening new avenues for quieter transformers:

Nanocrystalline cores:

These advanced materials offer even lower magnetostriction than amorphous alloys, reducing both noise and core losses.

Active vibration control:

Systems equipped with sensors and actuators can counteract vibration in real time by generating anti-phase signals—similar to active noise cancellation technology.

3D-printed core components:

Precision manufacturing using additive technologies allows for better control of geometry and material consistency, minimizing mechanical stress and ensuring uniform magnetic performance.

Minimizing power transformer core vibration and noise is a multidisciplinary challenge that involves material science, electromagnetic design, structural engineering, and acoustic control. The most effective noise reduction strategy combines high-quality core materials, precise mechanical assembly, optimized magnetic design, and proper installation practices. With ongoing advances in amorphous and nanocrystalline materials, as well as smart monitoring systems, modern transformers can achieve exceptional performance with minimal acoustic impact.

Ultimately, a quiet transformer is not only a sign of good design but also a reflection of reliability, efficiency, and long-term operational stability—qualities that are indispensable in today’s energy infrastructure.

+86-523 8891 6699

+86-523 8891 6699  +86-523 8891 8266

+86-523 8891 8266  info@tl-core.com

info@tl-core.com  No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

English

English Español

Español Türk

Türk 中文简体

中文简体