In modern power systems, transformers are indispensable equipment that plays a vital role in power transmission and distribution. The core component of the transformer, the transformer core, is the basis for the efficient operation of the entire device. The role of the core is to ensure the effective conversion of electrical energy, stabilize the transmission of current, and minimize energy loss.

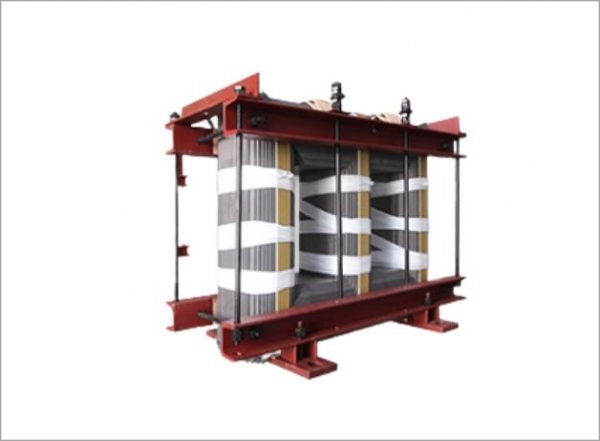

The transformer core is the core part of the transformer for conducting magnetic fields. Its main function is to provide a low-impedance path so that magnetic flux can flow effectively between the primary and secondary windings of the transformer. The core is usually composed of layers of silicon steel sheets that are stacked together to reduce the energy loss caused by the current passing through the conductor.

The working principle of the transformer is based on electromagnetic induction. The core realizes the transmission and conversion of electrical energy through the induced magnetic field. When the current passes through the primary winding of the transformer, an alternating magnetic field is generated in the core. This magnetic field is transmitted to the secondary winding through the core, thereby inducing the current in the secondary winding and completing the transmission and conversion of electrical energy.

The material of the transformer core is one of the important factors affecting the performance of the transformer. Common core materials are as follows:

Silicon steel sheet: Silicon steel sheet is the most commonly used transformer core material. It has good magnetic permeability and low hysteresis loss, which can effectively reduce energy loss and improve the efficiency of the transformer. Silicon steel sheets are usually coated with an insulating layer to reduce eddy current loss and enhance its insulation performance.

Non-oriented silicon steel sheet: The core of this material can provide lower losses and is suitable for high-frequency applications, such as high-frequency transformers. Its grain distribution is uniform, which can reduce hysteresis loss and improve the operating efficiency of the transformer.

Amorphous alloy material: Amorphous alloy is a new type of material that has emerged in recent years. It has very low core loss and is especially suitable for low-load and high-efficiency transformers. Despite its high cost, its high efficiency has made it widely used in some high-end applications.

Powdered iron core: In some specific small transformers, powdered iron core is also used to make the core. The magnetic properties of this material are relatively general, but due to its low cost, it is still used in some low-power applications.

The design of the transformer core directly affects the efficiency and performance of the transformer. In order to minimize energy loss, the core design of modern transformers tends to the following directions:

Laminated design: To reduce eddy current loss, the transformer core is usually composed of many thin steel sheets (usually silicon steel sheets) stacked together. This design can effectively reduce the eddy current loss generated by the current inside the core and improve the efficiency of the transformer. Each steel sheet has an insulating coating to ensure that the eddy current cannot propagate through the entire core.

Closed structure: The core of the transformer usually adopts a closed ring structure, which helps to reduce magnetic flux leakage, ensure that the magnetic field can be conducted more concentratedly, and improve the working efficiency of the transformer.

Optimize air gap design: The design of the air gap affects the working efficiency and load capacity of the transformer. In the design of the core, by precisely controlling the size of the air gap, the magnetic saturation phenomenon can be reduced and the performance of the transformer can be further improved.

Although the transformer core plays an irreplaceable role in the power system, it still faces some challenges and development directions:

Energy efficiency issues: With the continuous rise in energy costs, the energy efficiency requirements of transformers are getting higher and higher. The loss of the core, especially the hysteresis loss and eddy current loss, is still the main factor affecting the energy efficiency of the transformer. Therefore, the development of more efficient materials and designs is the direction of future development.

Material cost: The price of high-quality silicon steel sheets is high, which makes the production cost of transformers rise. To solve this problem, manufacturers are trying to adopt more cost-effective materials, such as amorphous alloys, to reduce production costs while ensuring high efficiency.

Environmental protection requirements: With the increasing global requirements for environmental protection, the materials and processes used in transformer production also need to comply with more environmental standards. The use of recyclable materials and the reduction of pollutant emissions during the production process have become the trend of future development.

Transformer cores are widely used in various aspects of the power system. Whether in urban power distribution, power supply of industrial equipment, or energy conversion in new energy systems, transformer cores play an irreplaceable role. Its design and material are directly related to the operating efficiency, stability and service life of the entire power equipment.

In the field of high-efficiency and low-loss transformers, with the advancement of technology, transformer core materials and designs are constantly innovating, further improving the energy utilization efficiency of the power system. Especially in modern applications such as high-voltage substations, smart grids and electric vehicle charging stations, technological innovation of transformer cores is crucial to improving the performance of the entire system.

As the core component in power transmission, the transformer core plays a decisive role in the efficiency and stability of the transformer. With the development of science and technology, the materials and designs of transformer cores are constantly improving, and in the future, more attention will be paid to energy efficiency, cost and environmental protection. As a key component of power equipment, the innovation and application of transformer cores will directly affect the development of the global power system and the improvement of energy efficiency.

+86-523 8891 6699

+86-523 8891 6699  +86-523 8891 8266

+86-523 8891 8266  info@tl-core.com

info@tl-core.com  No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

English

English Español

Español Türk

Türk 中文简体

中文简体