Oil-immersed transformers represent the backbone of electrical power distribution systems worldwide, serving critical roles in transmitting electricity from generation facilities to end users efficiently and reliably. These transformers utilize mineral oil or synthetic dielectric fluids to insulate electrical components while simultaneously providing cooling through convection and radiation. The oil surrounds the transformer core and windings completely, creating an environment that prevents electrical breakdown while managing the substantial heat generated during power conversion. Understanding the fundamental principles of oil-immersed transformer operation proves essential for engineers, facility managers, and maintenance personnel responsible for industrial power infrastructure.

The transformer core forms the magnetic circuit that enables voltage transformation through electromagnetic induction. Constructed from thin laminations of grain-oriented electrical steel, the core minimizes energy losses from eddy currents and hysteresis while providing efficient magnetic flux pathways. The immersion in transformer oil serves dual purposes: electrical insulation between high-voltage components and heat dissipation from the core and windings to the external environment. This cooling mechanism allows oil-immersed transformers to handle higher power loads than dry-type alternatives of comparable size, making them preferred choices for utility-scale applications and heavy industrial operations requiring robust, long-lasting power conversion equipment.

The transformer core utilizes grain-oriented electrical steel laminations stacked in precise configurations to create optimal magnetic circuits. These thin steel sheets, typically 0.23 to 0.35 millimeters thick, feature specialized crystal structure aligned in the rolling direction to minimize magnetic losses and maximize permeability. Manufacturing processes include cold rolling, decarburizing annealing, and coating with insulating layers that prevent inter-lamination current flow. The grain orientation concentrates magnetic properties along preferred directions, dramatically improving efficiency compared to non-oriented electrical steel. Modern high-grade core materials achieve remarkably low core losses, with premium grades offering specific losses below 1.0 watts per kilogram at standard test conditions.

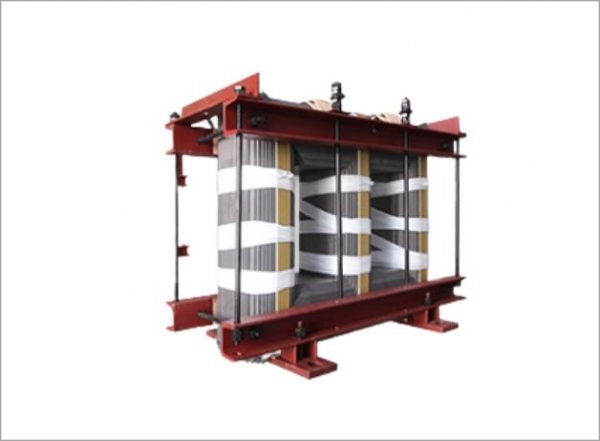

Core assembly configurations fall into two primary categories: core-type and shell-type designs, each offering distinct advantages for specific applications. Core-type transformers feature windings wrapped around vertical steel columns connected by horizontal yokes, creating rectangular or cruciform cross-sections. This construction simplifies winding installation and repair while providing excellent cooling access. Shell-type designs surround windings with magnetic steel on multiple sides, offering superior short-circuit strength and mechanical stability for large power transformers. The selection between these architectures depends on voltage levels, power ratings, impedance requirements, and mechanical stress considerations specific to individual installations.

| Core Type | Configuration | Advantages | Typical Applications |

| Core-Type | Windings around limbs | Easy maintenance, good cooling | Distribution, medium power |

| Shell-Type | Core surrounds windings | High mechanical strength | Large power transformers |

| Three-Limb | Three vertical columns | Compact, cost-effective | Three-phase systems |

| Five-Limb | Three main, two return limbs | Reduced height | Transport-limited installations |

Core joints require meticulous engineering to minimize magnetic reluctance and prevent localized heating. Step-lap or interleaved joint construction staggers lamination ends across multiple layers, distributing magnetic flux smoothly through joint regions. This technique reduces no-load losses and minimizes acoustic noise compared to simple butt joints. Advanced manufacturing employs laser-cutting and precision stacking to achieve tight tolerances, with modern cores reaching flux densities of 1.7 to 1.8 Tesla while maintaining acceptable loss levels. Proper core grounding prevents circulating currents through the core structure, with single-point grounding systems protecting against dangerous voltages developing between core and tank during fault conditions.

Transformer oil fulfills multiple critical functions beyond simple insulation and cooling. The dielectric fluid must withstand high electrical stresses without breakdown, typically demonstrating breakdown voltages exceeding 30 kilovolts for new oil and maintaining adequate values through service life. Mineral oils derived from petroleum distillation dominate the market due to favorable balance of cost, performance, and availability. These paraffinic or naphthenic base oils undergo extensive refining, including acid treatment, clay filtration, and hydrotreating to remove impurities, moisture, and compounds that could compromise electrical or thermal performance. The resulting product exhibits excellent dielectric strength, thermal stability, and oxidation resistance essential for decades of reliable service.

Thermal properties of transformer oil directly impact cooling effectiveness and operational capacity. The oil must efficiently absorb heat from core and windings, transport it through convection to cooling surfaces, and release it to the environment through tank walls or radiators. Viscosity represents a critical parameter, as excessively thick oil impedes convection currents while overly thin oil may not provide adequate film strength for bearings in tap changers. Most transformer oils maintain kinematic viscosities between 10 and 12 centistokes at 40 degrees Celsius, balancing flow characteristics with protective properties. Thermal conductivity, specific heat capacity, and thermal expansion coefficient further influence cooling system design and operational temperature ranges.

Alternative dielectric fluids address specific operational challenges or environmental concerns. Silicone fluids offer superior fire resistance with flash points exceeding 300 degrees Celsius, making them suitable for indoor installations or locations with stringent fire safety requirements. Natural ester fluids derived from vegetable oils provide biodegradability and environmental compatibility, increasingly specified for transformers near waterways or sensitive ecosystems. Synthetic esters combine performance advantages with improved environmental profiles. Each fluid type requires specific handling procedures, compatibility assessments with existing materials, and adapted maintenance practices to ensure optimal transformer performance and longevity.

Effective cooling system design determines transformer capacity, efficiency, and service life by maintaining operating temperatures within acceptable limits. Natural convection cooling, designated ONAN (Oil Natural Air Natural), relies on thermal gradients to circulate oil through the transformer and dissipate heat through tank surfaces and radiators. This passive approach offers reliability and low maintenance but limits power density. Forced air cooling, designated ONAF (Oil Natural Air Forced), adds fans to radiators, increasing heat dissipation capacity by 25 to 40 percent without circulating oil pumps. This configuration provides economical capacity enhancement for installations with variable loading patterns.

Forced oil circulation systems, designated OFAF (Oil Forced Air Forced) or OFWF (Oil Forced Water Forced), actively pump oil through cooling equipment for maximum heat transfer. External heat exchangers separate cooling function from the main tank, enabling compact designs with high power densities suitable for large utility transformers and industrial applications. Water-cooled systems achieve superior heat removal in space-constrained installations, though they introduce maintenance complexity and potential water contamination risks. Hybrid cooling combines natural and forced methods, automatically activating fans or pumps as load increases, optimizing efficiency across varying operating conditions while providing redundancy for critical applications.

Temperature monitoring and control systems protect transformers from thermal damage while maximizing utilization. Winding temperature indicators measure hottest-spot temperatures either directly through fiber-optic sensors or indirectly through thermal models based on top-oil temperature and load current. These instruments trigger alarms at preset thresholds and automatically activate supplemental cooling or shed non-essential loads to prevent insulation degradation. Modern digital relays integrate multiple temperature inputs with loading history to calculate remaining insulation life and predict maintenance requirements. Thermal imaging surveys identify cooling system deficiencies, blocked radiators, or abnormal hot spots requiring corrective action before failures occur.

Insulation system design coordinates multiple materials to withstand operating voltages, transient overvoltages, and environmental stresses throughout transformer service life. Solid insulation consisting of cellulose paper and pressboard separates conductors, supports windings mechanically, and provides barriers against oil contamination migration. The cellulose materials undergo extensive drying and vacuum processing before oil impregnation to remove moisture that would compromise dielectric strength. Oil-impregnated cellulose exhibits breakdown strengths exceeding 15 kilovolts per millimeter when properly processed, though actual working stresses remain far below these values to ensure adequate safety margins.

Insulation aging represents the primary life-limiting factor for oil-immersed transformers, with thermal, electrical, and mechanical stresses gradually degrading cellulose polymer chains. Thermal aging accelerates exponentially with temperature, following relationships where each 6 to 10 degree Celsius increase halves insulation life expectancy. Moisture presence dramatically accelerates degradation, making moisture control essential for longevity. Electrical stresses from partial discharge activity erode insulation surfaces, while mechanical forces from short circuits and through-fault currents compress and damage solid insulation. Comprehensive insulation design accounts for all degradation mechanisms, specifying materials, dimensions, and configurations that ensure decades of reliable operation under expected service conditions.

Bushings provide insulated pathways for conductors passing through grounded transformer tanks, representing critical components requiring careful specification and maintenance. High-voltage bushings incorporate oil-impregnated paper, resin-bonded paper, or resin-impregnated paper insulation systems designed to manage extremely high electric field stresses. Capacitance grading distributes voltage stresses uniformly along bushing length, preventing localized stress concentrations that could initiate failure. Proper bushing installation requires clean, dry conditions and torque specifications to ensure optimal electrical contact and mechanical stability. Regular monitoring of bushing power factor, capacitance, and dissolved gas analysis detects developing problems before catastrophic failures interrupt power delivery.

Preventive maintenance programs extend transformer life and prevent unexpected failures through systematic inspection, testing, and corrective actions. Oil analysis forms the foundation of condition-based maintenance, with dissolved gas analysis identifying incipient faults through characteristic gas generation patterns. Thermal faults produce ethylene and methane, while electrical discharges generate hydrogen and acetylene. Tracking gas concentrations over time reveals developing problems, allowing intervention before extensive damage occurs. Additional oil tests measure dielectric strength, acidity, moisture content, interfacial tension, and oxidation inhibitor depletion, providing comprehensive assessment of oil condition and required reclamation or replacement timing.

Electrical testing validates transformer performance and identifies degradation requiring attention. Insulation resistance measurements detect moisture contamination or insulation deterioration through megohm readings between windings and ground. Power factor testing reveals insulation quality through dielectric loss measurements, with increasing power factor indicating deteriorating insulation condition. Turns ratio testing confirms proper winding configuration and detects shorted turns. Winding resistance measurements identify loose connections, tap changer contact problems, or conductor damage. Frequency response analysis compares impedance signatures across wide frequency ranges, detecting mechanical deformation from short-circuit forces or transportation damage.

Thermographic inspection identifies hot spots, cooling system problems, and electrical connection issues through infrared imaging. Elevated temperatures at tap changers suggest contact wear or improper settings requiring correction. Hot radiator sections indicate blocked oil flow needing investigation. Regular visual inspections detect oil leaks, corrosion, loose fittings, damaged gauges, and other visible defects. Moisture monitoring through online sensors provides continuous tracking of water content in oil, triggering alarms when dehydration becomes necessary. Comprehensive maintenance programs integrate multiple diagnostic techniques, scheduling interventions based on actual condition rather than arbitrary time intervals, optimizing reliability while controlling costs.

Safety systems protect personnel, equipment, and facilities from transformer failures and operational hazards. Pressure relief devices including sudden pressure relays and rupture disks prevent tank rupture during internal fault events that rapidly generate gas. Buchholz relays installed in conservator piping detect gas accumulation from minor faults and oil flow surges from major disturbances, providing early warning and fault isolation. Temperature-activated alarms and automatic shutdown systems prevent thermal runaway conditions. Proper grounding and bonding eliminate dangerous touch and step potentials around transformer installations, while safety barriers and signage restrict access to energized equipment.

Fire protection requirements vary based on transformer location, fluid type, and applicable codes. Indoor transformers or those near buildings require fire-resistant fluids, fire suppression systems, or physical separation barriers. Oil containment systems prevent environmental contamination from spills or leaks, with secondary containment volumes sufficient to hold entire transformer oil capacity plus firefighting water. Automatic fire suppression using water spray, foam, or gaseous agents activates based on heat or flame detection. Regular fire system testing and maintenance ensures readiness for emergency response. Coordination with local fire departments familiarizes responders with transformer-specific hazards and appropriate firefighting techniques.

Environmental regulations govern transformer oil management, polychlorinated biphenyl (PCB) contamination, and end-of-life disposal. PCB-containing transformers require special handling, labeling, and eventual replacement or disposal following strict protocols. Oil reclamation and recycling programs reduce waste and environmental impact while extending oil service life. Spill prevention and response planning minimizes contamination risks, with regular inspections identifying potential leak sources before failures occur. Modern transformer designs incorporate environmental considerations including reduced oil volumes, biodegradable fluids, and recyclable materials, balancing performance requirements with sustainability goals throughout equipment lifecycles.

Selecting appropriate oil-immersed transformers for industrial applications requires comprehensive analysis of electrical requirements, environmental conditions, and operational constraints. Power rating determination begins with maximum load calculations including diversity factors and future expansion allowances. Voltage specifications must match utility supply characteristics and facility distribution requirements, with impedance selection balancing short-circuit limitation against voltage regulation. Three-phase transformers offer compact, economical solutions for balanced loads, while single-phase units provide flexibility for special applications or redundant configurations.

Environmental factors significantly influence transformer specification and installation design. Ambient temperature ranges, altitude, seismic activity, and pollution levels all affect transformer selection and derating requirements. High-altitude installations require voltage derating or enhanced insulation due to reduced air cooling effectiveness. Seismic zones necessitate specialized anchoring and structural supports. Coastal or industrial environments with high pollution levels require increased creepage distances on bushings and insulators. Indoor installations may mandate specific fluid types, noise levels, or cooling configurations compatible with building constraints.

Economic analysis balances initial purchase costs against lifetime operating expenses including losses, maintenance, and expected service life. High-efficiency transformers cost more initially but reduce energy losses, often paying back premium pricing through electricity savings within several years. Reliability requirements influence specification of redundancy, monitoring equipment, and spare parts inventory. Critical processes may justify parallel transformer installation with automatic transfer capability. Total cost of ownership calculations incorporating all factors guide optimal transformer selection for specific applications, ensuring reliable, efficient power delivery throughout expected service life while meeting budget constraints and operational requirements.

+86-523 8891 6699

+86-523 8891 6699  +86-523 8891 8266

+86-523 8891 8266  info@tl-core.com

info@tl-core.com  No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

English

English Español

Español Türk

Türk 中文简体

中文简体