Silicon steel, also known as electrical steel or transformer steel, represents a specialized iron-silicon alloy engineered specifically for electromagnetic applications requiring efficient magnetic flux conduction with minimal energy losses. The addition of silicon to pure iron, typically ranging from 0.5 to 6.5 percent by weight, fundamentally alters the material's electrical and magnetic characteristics. This silicon content increases electrical resistivity, which dramatically reduces eddy current losses during alternating magnetic field exposure. The material simultaneously maintains high magnetic permeability and saturation flux density essential for efficient energy conversion in transformers, motors, generators, and other electromagnetic devices.

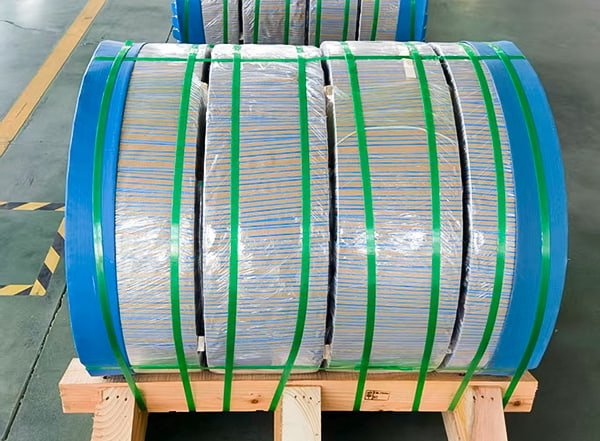

The slitting process transforms wide master coils of silicon steel into narrower coils with precise widths matching specific application requirements. This manufacturing step proves crucial for electrical equipment manufacturers who need exact dimensional specifications for lamination stamping, core assembly, and other fabrication processes. Slitting coils allows producers to purchase material in optimal widths for their operations, reducing waste and improving production efficiency. The precision achieved through modern slitting technology ensures consistent material properties across the coil width, maintaining the electrical performance characteristics essential for high-efficiency electromagnetic devices.

Silicon steel exists in two primary categories based on crystal structure and magnetic properties: grain-oriented electrical steel (GOES) and non-oriented electrical steel (NOES). Grain-oriented steel undergoes specialized processing including cold rolling and high-temperature annealing that aligns the crystal structure predominantly in the rolling direction. This alignment creates highly directional magnetic properties, with dramatically superior permeability and lower core losses when magnetic flux flows parallel to the rolling direction. The Goss texture developed during processing produces magnetic properties in the rolling direction that can be ten times better than properties perpendicular to this direction.

Non-oriented electrical steel maintains more uniform magnetic properties in all directions within the plane of the sheet, making it suitable for rotating machinery where magnetic flux changes direction continuously. The manufacturing process for non-oriented grades focuses on achieving consistent properties throughout the material rather than optimizing directional characteristics. When slitting grain-oriented silicon steel coils, maintaining proper orientation alignment becomes critical, as the magnetic advantages exist only when flux travels along the preferred grain direction. Transformer manufacturers utilize this directional property by orienting laminations so magnetic flux follows the rolling direction throughout the core structure.

| Steel Type | Grain Structure | Typical Core Loss (W/kg) | Primary Applications |

| Grain-Oriented | Aligned crystals | 0.9-1.3 | Transformers, inductors |

| High-Grade GOES | Highly aligned | 0.7-0.9 | Power transformers |

| Non-Oriented | Random orientation | 2.5-7.5 | Motors, generators |

| Domain Refined | Laser-treated | 0.6-0.8 | Ultra-efficient transformers |

Advanced processing techniques including domain refinement further enhance grain-oriented steel performance. Laser scribing or mechanical scribing creates controlled surface patterns that subdivide magnetic domains, reducing domain wall movement losses. This treatment can reduce core losses by 5 to 15 percent compared to conventional grain-oriented steel, though it adds manufacturing cost. When slitting domain-refined materials, protecting the treated surface from damage preserves these efficiency benefits. The precision slitting process must avoid edge burrs, mechanical stress, or coating damage that could compromise the carefully engineered magnetic domain structure.

Material thickness represents a critical factor influencing electrical efficiency, with thinner laminations producing lower eddy current losses in alternating magnetic fields. Eddy currents are circular electrical currents induced within conductive materials exposed to changing magnetic flux. These parasitic currents generate heat without contributing to useful work, representing pure energy loss. The magnitude of eddy current losses relates directly to material thickness squared, meaning halving lamination thickness reduces eddy current losses to one-quarter of the original value. This mathematical relationship drives the trend toward progressively thinner electrical steel grades for high-efficiency applications.

Common silicon steel thicknesses range from 0.18 to 0.50 millimeters, with specific selection depending on application frequency and efficiency requirements. Power transformers operating at 50 or 60 Hertz typically utilize 0.23, 0.27, or 0.30 millimeter material, balancing core loss reduction against manufacturing cost and mechanical handling considerations. Higher frequency applications including aerospace power systems, high-frequency transformers, and certain motor designs employ thinner gauges of 0.18 or 0.20 millimeters to minimize eddy current losses at elevated frequencies. The slitting process must maintain thickness uniformity across coil width to ensure consistent electrical performance in finished devices.

Insulating coatings applied to silicon steel surfaces provide electrical isolation between stacked laminations, preventing current flow perpendicular to the sheet plane. These coatings, typically composed of inorganic compounds or specialized resins, add only micrometers of thickness while providing effective electrical insulation. The coating must withstand stamping operations, annealing temperatures if applicable, and service conditions without degradation. Slitting operations must preserve coating integrity along cut edges to maintain insulation effectiveness. Some advanced slitting systems employ specialized cutting techniques that minimize coating damage and reduce the formation of conductive burrs along slit edges.

The slitting process employs precision cutting equipment to divide wide master coils into multiple narrower coils with exact width specifications. Modern slitting lines utilize rotary shear knives, arranged in adjustable arbors, that simultaneously cut the moving steel strip at multiple positions across its width. The cutting mechanism involves overlapping circular blades operating like scissors, producing clean edges with minimal burr formation. Maintaining sharp, properly adjusted tooling ensures cut quality that preserves material properties and dimensional accuracy. Dull or misaligned cutting tools create rough edges, excessive burrs, and potential mechanical stress that can degrade magnetic performance near cut edges.

Width tolerance control during slitting directly impacts downstream manufacturing efficiency and product quality. Transformer and motor manufacturers require precise lamination widths to achieve proper core stack dimensions and maintain design performance specifications. Typical slitting tolerances for silicon steel range from ±0.1 to ±0.3 millimeters depending on material grade and customer requirements. Advanced slitting lines incorporate laser measurement systems that continuously monitor slit widths during production, automatically adjusting knife positions to maintain tolerances. This real-time process control ensures consistent output quality across entire coil lengths and between different production runs.

Edge quality resulting from slitting operations influences both magnetic performance and subsequent fabrication processes. Clean, straight edges with minimal burrs facilitate smooth feeding through stamping dies and reduce tool wear during lamination blanking operations. Burrs and rough edges can create localized stress concentrations that increase core losses in the affected regions. Additionally, sharp burrs may puncture insulating coatings on adjacent laminations during stacking, creating electrical shorts that increase eddy current losses. Quality slitting operations balance cutting speed, blade sharpness, blade overlap, and other parameters to optimize edge quality while maintaining production efficiency.

Mechanical stress introduced during slitting and handling can locally degrade silicon steel's magnetic properties through several mechanisms. The cutting action creates residual stresses near slit edges, altering crystal structure and introducing localized strain that increases core losses and reduces permeability in affected zones. Excessive tension during unwinding, slitting, and rewinding operations can plastically deform the thin material, creating permanent stress patterns that persist in finished products. Careful process design minimizes these detrimental effects through appropriate tension control, proper blade maintenance, and optimized cutting parameters.

Stress relief annealing after slitting can restore magnetic properties degraded by mechanical processing, though this adds cost and complexity to the manufacturing sequence. The annealing process involves heating material to temperatures between 750 and 850 degrees Celsius in controlled atmospheres that prevent oxidation and decarburization. This thermal treatment allows stressed crystal structures to relax and recrystallize, recovering the magnetic performance characteristics of the original material. However, many applications utilize silicon steel in the as-slit condition, making process optimization to minimize stress introduction the preferred approach for maintaining efficiency.

Coil handling procedures throughout the slitting process significantly impact final material quality. Proper mandrel sizing, appropriate coiling tension, and careful edge alignment during rewinding prevent mechanical damage and dimensional distortion. Coil packaging must protect slit edges from impact damage and prevent contamination that could affect surface properties. Storage and transportation conditions should avoid excessive temperature variations, humidity exposure, or mechanical shock that might degrade material characteristics. These seemingly minor considerations collectively determine whether precision-slit silicon steel coils deliver their full electrical efficiency potential in finished electromagnetic devices.

Slitting silicon steel coils to application-specific widths dramatically reduces material waste in downstream manufacturing operations. Transformer and motor manufacturers blanking circular or rectangular laminations from steel strip achieve optimal material utilization when strip width closely matches lamination dimensions. Purchasing oversized material and trimming excess during fabrication wastes expensive electrical steel and increases production costs. Precision slitting allows manufacturers to order exact widths that minimize trim waste, reducing both material costs and scrap handling expenses. This waste reduction directly improves manufacturing economics while supporting sustainability goals through reduced material consumption.

The flexibility offered by slitting operations enables manufacturers to source material in economically optimal master coil widths while obtaining the specific dimensions needed for diverse product lines. Steel producers achieve maximum efficiency manufacturing wide master coils that minimize edge trim and production complexity. Slitting service centers or integrated manufacturers then convert these wide coils into the numerous width specifications required by electrical equipment producers. This two-stage approach optimizes efficiency across the entire supply chain, reducing costs at both steel production and equipment manufacturing levels.

Just-in-time inventory strategies benefit from slitting capabilities that provide quick delivery of specific width requirements in quantities matching production schedules. Rather than stocking numerous width variations in large quantities, manufacturers can maintain inventory in a few standard master coil sizes and slit to order as needed. This approach reduces inventory carrying costs, minimizes working capital requirements, and ensures material freshness by reducing storage time between production and use. The economic advantages complement the technical benefits of precision slitting in creating overall value for electrical equipment manufacturers.

Transformer core construction directly benefits from precision-slit silicon steel coils through improved assembly efficiency and enhanced electrical performance. Core builders utilize slit coils matching specific lamination widths required for their designs, eliminating secondary trimming operations and associated waste. The dimensional accuracy of precision slitting ensures uniform core stack dimensions, maintaining designed air gaps, flux densities, and electrical characteristics. Consistent lamination widths facilitate automated stacking processes, improving production speed and reducing labor costs while maintaining quality consistency.

Core loss performance depends heavily on lamination quality, including edge condition, dimensional accuracy, and freedom from mechanical damage. Precision slitting that maintains excellent edge quality throughout coil length ensures each lamination contributes minimal excess loss to the overall core. The cumulative effect across thousands of laminations in a transformer core significantly impacts total no-load losses and operational efficiency. Premium transformers utilizing high-grade grain-oriented steel with optimized slitting can achieve core losses 30 to 50 percent lower than designs using conventional materials and processing, translating to substantial energy savings over decades of service life.

Step-lap core construction, which staggers lamination joints across multiple layers to reduce magnetic reluctance, requires precise width control to achieve designed overlaps and gaps. Slitting tolerances directly affect step-lap geometry and consequently core performance. Tight width control enables optimized step-lap designs that minimize localized flux concentrations and associated losses at lamination joints. This advanced core construction technique, combined with precision-slit high-grade silicon steel, achieves efficiency levels required by modern energy conservation standards and environmental regulations worldwide.

Electric motors and generators utilize non-oriented silicon steel slit to precise widths for stator and rotor lamination production. The rotating magnetic fields in these machines require isotropic magnetic properties that non-oriented grades provide. Slitting enables motor manufacturers to obtain exact widths matching their stamping die designs, minimizing material waste while ensuring dimensional consistency across production runs. High-efficiency motor designs increasingly specify premium silicon steel grades with low core losses, making precision slitting essential for delivering the material quality required to meet efficiency regulations and customer performance expectations.

The global trend toward higher motor efficiency standards drives demand for improved silicon steel materials and processing. International efficiency standards including IE3, IE4, and emerging IE5 classifications require progressively lower losses, achievable through optimized materials and manufacturing processes. Precision-slit silicon steel coils support these efficiency improvements by ensuring lamination quality that minimizes core losses while maintaining the mechanical strength and dimensional accuracy needed for reliable motor operation. The cost premium for higher-grade materials and precision processing proves economically justified through reduced operating costs and regulatory compliance.

Specialized motor applications including high-speed machines, electric vehicle traction motors, and servo motors impose demanding requirements on silicon steel materials and processing. These applications often require thinner gauges, tighter tolerances, and superior surface quality compared to standard industrial motors. Advanced slitting capabilities providing exceptional dimensional control and edge quality enable manufacturers to meet these challenging specifications. The resulting motors deliver the high power density, efficiency, and reliability essential for modern automotive, aerospace, and industrial automation applications where performance requirements continue advancing rapidly.

Comprehensive quality control throughout the slitting process ensures silicon steel coils meet electrical and mechanical specifications critical for end-use performance. Dimensional inspection verifies width accuracy, thickness uniformity, and coil geometry using precision measurement equipment including laser micrometers, coordinate measuring machines, and automated optical systems. These inspections occur at multiple points during processing to detect and correct deviations before significant material quantity is affected. Statistical process control techniques track measurements over time, identifying trends that might indicate developing equipment issues requiring maintenance or adjustment.

Magnetic property testing validates that slitting operations haven't degraded the electrical performance characteristics essential for efficient electromagnetic devices. Standard tests measure specific core loss, permeability, and magnetic flux density using Epstein frame or single sheet tester methodologies defined by international standards including IEC, ASTM, and JIS specifications. Samples taken from slit coils undergo these tests to confirm compliance with grade specifications and detect any processing-induced property changes. Advanced facilities may employ online testing systems that continuously monitor magnetic properties during production, providing immediate feedback for process optimization.

Surface quality inspection examines coating condition, edge quality, and freedom from defects that could impact electrical performance or downstream processing. Visual inspection identifies obvious defects while specialized techniques including eddy current testing detect subtle coating damage or material flaws. Edge profile measurement quantifies burr height and edge straightness, ensuring compatibility with customer stamping operations and core assembly processes. Documentation systems track all quality measurements, maintaining traceability from master coil through slitting to final delivery, supporting continuous improvement initiatives and providing evidence of conformance to customer specifications and industry standards.

+86-523 8891 6699

+86-523 8891 6699  +86-523 8891 8266

+86-523 8891 8266  info@tl-core.com

info@tl-core.com  No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

English

English Español

Español Türk

Türk 中文简体

中文简体