Silicon steel slitting coils play a critical role in the manufacturing of electrical transformers, motors, and other electromagnetic devices. They are specially engineered steel sheets enriched with silicon, which improves their magnetic properties and reduces energy loss. By slitting these coils into precise widths, manufacturers can create high-quality transformer cores with optimized performance. Understanding how silicon steel slitting coils contribute to transformer efficiency and performance requires an exploration of their material properties, manufacturing processes, and applications in modern electrical engineering.

Silicon steel, often referred to as electrical steel, is a type of steel that contains a small percentage of silicon, typically between 2% and 4%. The addition of silicon enhances the electrical and magnetic properties of the steel, making it ideal for use in transformer cores and other electromagnetic applications.

Silicon steel is typically produced in two forms: grain-oriented (GO) and non-grain-oriented (NGO). Grain-oriented silicon steel is particularly important for transformers because its magnetic grains are aligned to minimize energy loss in the direction of magnetic flux.

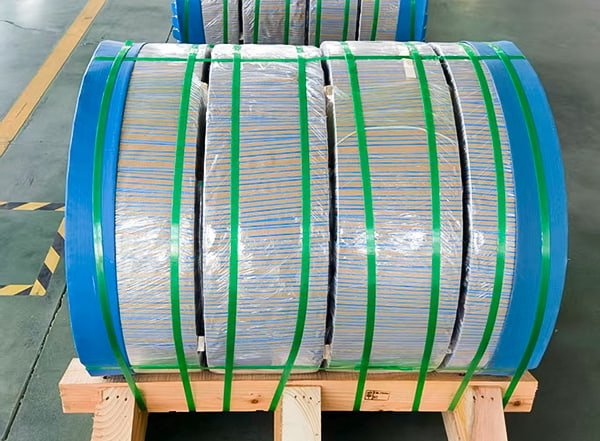

Silicon steel slitting coils are large rolls of silicon steel that have been slit into narrower strips to meet the specifications required for transformer core lamination. Slitting is the process of cutting wide steel coils into precise widths using mechanical or laser slitting machines. The goal is to produce uniform strips that can be stacked and laminated into high-performance transformer cores.

The slitting process must be carefully controlled to prevent edge burrs, scratches, or deformation, which can adversely affect magnetic performance.

Transformer efficiency is heavily influenced by the properties of the core material. Silicon steel slitting coils directly contribute to efficiency in several ways:

Core losses, also known as iron losses, consist of hysteresis loss and eddy current loss:

By using high-quality silicon steel slitting coils, manufacturers can minimize core losses, which directly improves transformer efficiency.

Silicon steel’s high permeability allows magnetic flux to flow more easily through the core. Slitted coils, precisely laminated without gaps or distortions, ensure that magnetic flux is distributed evenly. This reduces localized saturation and ensures that the transformer operates at optimal efficiency.

Lower core losses also mean reduced heat generation. Excess heat in transformers can degrade insulation, reduce lifespan, and increase maintenance costs. Using silicon steel slitting coils helps maintain lower operating temperatures, enhancing reliability and efficiency.

Grain-oriented (GO) silicon steel is particularly effective in transformer applications:

Non-grain-oriented (NGO) silicon steel is used in applications such as motors, where magnetic flux changes direction continuously. In transformers, GO silicon steel is preferred for the core laminations due to its superior efficiency.

The slitting process itself has a significant impact on transformer performance:

Manufacturers often use high-precision slitting lines equipped with tension control, laser guidance, and inspection systems to maintain quality. The goal is to produce strips that meet strict tolerances for transformer manufacturing.

Silicon steel slitting coils are used in various transformer types:

Used in electrical grids, these transformers require high-efficiency cores to minimize energy loss during power transmission. GO silicon steel strips are laminated to form cores with low hysteresis and eddy current losses, improving overall efficiency.

Smaller transformers that step down voltage for residential or commercial use benefit from thin, precisely slitted silicon steel strips that reduce losses and heat generation.

Used for measurement and protection, these transformers rely on accurate magnetic flux transfer. High-quality silicon steel slitting coils ensure precise performance and minimal loss.

Transformers in renewable energy systems, electric vehicles, and industrial machinery also use slitted silicon steel to maximize efficiency and maintain consistent performance under varying loads.

To ensure that silicon steel slitting coils improve transformer efficiency, manufacturers must adhere to strict quality standards:

International standards, such as ASTM A677, IEC 60404, and JIS C2552, guide the production and testing of silicon steel coils for transformer applications.

Using high-quality slitting coils provides several benefits for transformer efficiency and performance:

Modern advancements in silicon steel slitting coil production are further improving transformer performance:

These innovations continue to optimize transformer efficiency while reducing manufacturing costs.

Silicon steel slitting coils are a cornerstone of modern transformer manufacturing. By providing high magnetic permeability, low core loss, and precise lamination capabilities, these coils directly improve transformer efficiency and performance. Grain-oriented silicon steel enhances magnetic flux alignment, while the slitting process ensures uniformity, smooth edges, and optimal thickness for laminated cores.

From power transmission to industrial machinery, high-quality silicon steel slitting coils contribute to energy savings, reduced heat generation, reliable operation, and longer transformer lifespan. As technology advances, precision slitting, ultra-thin gauges, and innovative coatings continue to enhance the role of silicon steel in achieving efficient and sustainable electrical systems.

For manufacturers and engineers, understanding the material properties, slitting techniques, and application-specific requirements of silicon steel slitting coils is essential to designing transformers that deliver maximum performance and efficiency.

+86-523 8891 6699

+86-523 8891 6699  +86-523 8891 8266

+86-523 8891 8266  info@tl-core.com

info@tl-core.com  No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

English

English Español

Español Türk

Türk 中文简体

中文简体