Transformer cores are at the heart of modern power distribution systems. Their function is to provide a magnetic path that efficiently transfers energy from the primary to the secondary winding of the transformer. The performance, efficiency, and durability of a transformer depend largely on the material used in its core. Two of the most widely used core materials in power distribution transformers are amorphous alloys and silicon steel. Both materials have unique characteristics, advantages, and limitations that influence their suitability in specific applications.

This article explores the key differences between amorphous alloy and silicon steel transformer cores in terms of structure, magnetic properties, energy efficiency, environmental impact, cost, and long-term applications.

Amorphous Alloy

Silicon Steel

Key Difference: Amorphous alloys lack a crystalline structure, while silicon steel has a defined crystalline grain structure. This fundamental difference explains their contrasting magnetic and electrical behaviors.

Amorphous Alloy

Silicon Steel

Key Difference: Amorphous alloys excel in minimizing energy loss but have lower magnetic flux density capacity compared to silicon steel.

Amorphous Alloy

Silicon Steel

Key Difference: Amorphous alloy cores dramatically reduce no-load losses, while silicon steel cores perform better in situations requiring higher flux density and load-carrying capacity.

Amorphous Alloy

Silicon Steel

Key Difference: Amorphous alloys contribute more to energy conservation and emission reduction, while silicon steel’s long-term environmental cost is higher.

Amorphous Alloy

Silicon Steel

Key Difference: Silicon steel offers greater mechanical strength and design flexibility, whereas amorphous alloys are more fragile and challenging to process.

Amorphous Alloy

Silicon Steel

Key Difference: Amorphous alloys are costlier initially but provide savings over time, while silicon steel offers a more affordable upfront option.

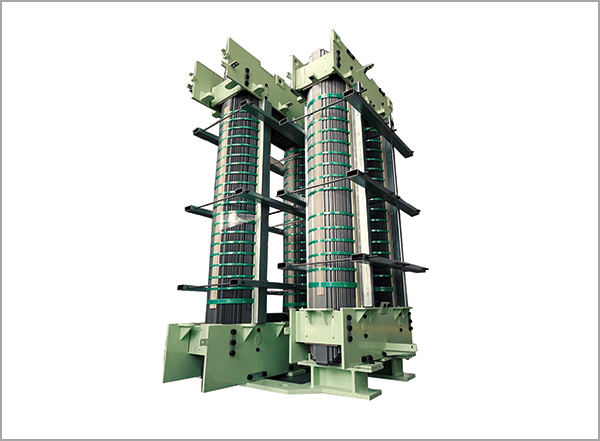

Amorphous Alloy Transformer Cores

Silicon Steel Transformer Cores

Key Difference: Amorphous alloys are niche but growing in distribution transformer applications, while silicon steel remains the standard for most power and industrial transformers.

The choice between amorphous alloy and silicon steel transformer cores depends on a trade-off between efficiency, cost, durability, and application requirements.

Ultimately, the decision should be based on lifecycle cost analysis, energy policy considerations, and operational requirements. As energy efficiency becomes a global priority, amorphous alloys are likely to gain more traction, but silicon steel will continue to play a critical role in the backbone of power distribution systems.

+86-523 8891 6699

+86-523 8891 6699  +86-523 8891 8266

+86-523 8891 8266  info@tl-core.com

info@tl-core.com  No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

English

English Español

Español Türk

Türk 中文简体

中文简体