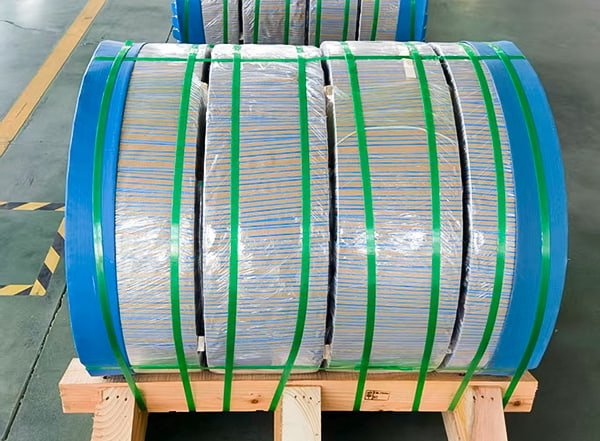

Silicon steel slitting coils are narrow-width coils produced by slitting wide silicon steel master coils into precise strip widths. Silicon steel, also known as electrical steel, is an iron-silicon alloy specifically engineered for superior magnetic properties. These slitting coils are widely used as core materials in transformers, motors, generators, and other electromagnetic equipment where efficiency and magnetic performance are critical.

By converting large coils into customized widths, silicon steel slitting coils enable manufacturers to optimize material usage, improve lamination accuracy, and reduce processing waste during downstream stamping or cutting operations.

The performance of silicon steel slitting coils is closely tied to their chemical composition. Typically, silicon content ranges from 0.5% to 3.5%, which significantly improves electrical resistivity and reduces core losses caused by eddy currents.

Silicon increases the resistivity of steel, minimizing energy loss during alternating magnetic cycles. It also enhances magnetic permeability, allowing magnetic flux to pass more easily through the material. These properties are essential for applications requiring high efficiency and low heat generation.

Depending on the manufacturing process, silicon steel may be grain-oriented or non-grain-oriented. Grain-oriented silicon steel slitting coils are optimized for unidirectional magnetic flux, while non-grain-oriented types support multi-directional magnetic fields, making them suitable for rotating machinery.

The production of silicon steel slitting coils involves precision equipment and strict quality control to maintain magnetic performance and dimensional accuracy. The slitting process is designed to avoid mechanical stress that could degrade magnetic properties.

Wide silicon steel master coils are first inspected for thickness consistency, surface quality, and coating integrity. These coils are typically supplied in annealed and coated form to protect against oxidation and inter-laminar short circuits.

High-precision slitting machines cut the master coil into narrow strips with tight width tolerances. Edge quality is carefully controlled to prevent burrs, which could interfere with stacking efficiency and insulation performance in laminated cores.

Selecting the correct silicon steel slitting coil requires understanding several technical parameters that directly influence performance and compatibility with end-use equipment.

Silicon steel slitting coils are broadly classified into grain-oriented (GO) and non-grain-oriented (NGO) types, each serving distinct industrial applications.

| Property | Grain-Oriented | Non-Grain-Oriented |

| Magnetic Direction | Highly directional | Multi-directional |

| Core Loss | Very low | Moderate |

| Main Applications | Transformers | Motors and generators |

| Cost Level | Higher | Moderate |

Silicon steel slitting coils are a core material in power and distribution transformers. Grain-oriented slitting coils are precisely cut and stacked to align with the magnetic flux direction, minimizing hysteresis and eddy current losses.

Accurate slitting ensures consistent lamination dimensions, which directly impacts transformer efficiency, noise levels, and operational lifespan.

Non-grain-oriented silicon steel slitting coils are widely used in electric motors, generators, and alternators. These applications require uniform magnetic properties in multiple directions due to rotating magnetic fields.

The use of precisely slit coils improves stamping accuracy for stator and rotor laminations, enhancing torque output and reducing energy losses.

Using silicon steel slitting coils offers several practical advantages over processing wide master coils in-house. These benefits contribute to improved production efficiency and cost control.

Silicon steel slitting coils are typically supplied with insulation coatings that reduce inter-laminar eddy currents and protect against corrosion. Common coatings include inorganic phosphate layers and organic resin-based films.

Choosing the appropriate coating type is essential for maintaining insulation resistance, especially in high-frequency or high-temperature applications.

Strict quality control ensures that silicon steel slitting coils meet international standards such as ASTM, JIS, IEC, and EN. Testing focuses on magnetic loss, thickness tolerance, coating adhesion, and edge condition.

Reliable suppliers provide detailed inspection reports and traceability documentation to support consistent downstream manufacturing.

Selecting suitable silicon steel slitting coils requires balancing magnetic performance, processing requirements, and cost considerations. Buyers should evaluate end-use equipment, operating frequency, and efficiency targets before finalizing specifications.

Working closely with experienced slitting service providers helps ensure optimal coil width, edge quality, and coating compatibility for specific applications.

Silicon steel slitting coils play a critical role in modern electrical and energy systems. Their tailored dimensions, excellent magnetic properties, and production efficiency make them indispensable for transformers, motors, and generators.

By understanding material characteristics and application requirements, manufacturers can leverage silicon steel slitting coils to achieve higher efficiency, reliability, and long-term performance.

+86-523 8891 6699

+86-523 8891 6699  +86-523 8891 8266

+86-523 8891 8266  info@tl-core.com

info@tl-core.com  No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

English

English Español

Español Türk

Türk 中文简体

中文简体