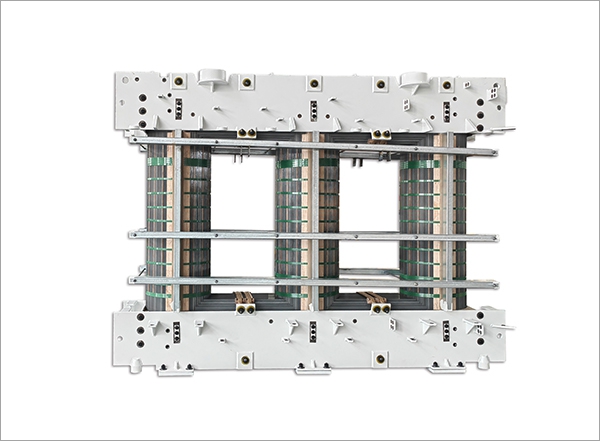

The power distribution transformer core is a critical component that directly affects efficiency, reliability, and the overall lifespan of transformers. Proper maintenance ensures minimal energy losses, reduced downtime, and enhanced operational safety. This article explores practical maintenance practices to extend the life and performance of transformer cores.

Visual inspection is the first line of defense in maintaining transformer cores. Regular checks allow operators to identify physical damage, corrosion, or insulation issues early.

Inspect for signs of cracks, dents, or deformation in the core laminations. Physical damage can lead to short circuits or uneven magnetic flux distribution, impacting transformer efficiency.

Check for rust or corrosion, especially in humid environments. Corrosion can deteriorate the magnetic properties of the core, leading to increased losses and reduced efficiency. Protective coatings or anti-corrosion treatments can help prevent damage.

Temperature is a critical parameter in transformer core performance. Excessive heat accelerates insulation degradation and increases core losses.

Install temperature sensors or thermocouples to continuously monitor the core temperature. Maintaining optimal temperature prevents thermal stress and prolongs the lifespan of the transformer.

Regularly review temperature trends to detect anomalies or overheating patterns. Sudden spikes may indicate issues such as overloading, poor ventilation, or core saturation.

Electrical tests provide insights into core condition that may not be visible during inspections.

Measuring core loss helps identify inefficiencies. Increased losses can indicate insulation breakdown, lamination damage, or magnetic saturation. Regular testing ensures timely corrective measures.

Perform insulation resistance tests to detect deterioration or moisture ingress. Low resistance readings may signal compromised insulation, which can lead to short circuits or transformer failure.

Dust, dirt, and other contaminants can affect transformer core performance. Maintaining a clean environment ensures efficient magnetic flux and prevents overheating.

Use dry cleaning methods or vacuum systems to remove accumulated dust. Avoid using water or chemical cleaners that may damage insulation or metallic components.

Keep the transformer core dry by monitoring humidity levels and using silica gel or dehumidifiers in enclosed transformer rooms. Moisture can cause insulation failure and accelerate corrosion.

Loose core laminations or vibration issues can cause noise, mechanical stress, and increased core losses. Ensuring proper mechanical stability is essential for long-term reliability.

Regularly check and tighten core bolts to ensure laminations remain aligned and compact. Loose laminations may result in vibration and excessive heat generation.

Install vibration dampers or pads where necessary to reduce mechanical stress and prolong core life. Proper vibration management prevents insulation damage and maintains magnetic performance.

Some transformer cores may include moving components in tap changers or cooling systems. Proper lubrication prevents wear and ensures smooth operation.

Use manufacturer-recommended lubricants to prevent contamination or chemical reactions that could compromise core insulation. Regular lubrication reduces friction and mechanical wear.

Establish regular intervals for checking lubrication and moving components. Timely maintenance prevents operational failures and extends transformer life.

Maintaining records of inspections, tests, and repairs is critical for predictive maintenance. Historical data helps identify patterns and prevents unexpected failures.

Document every inspection, test, and repair activity. Logs allow engineers to track transformer performance and schedule proactive interventions before failures occur.

Use predictive analytics based on temperature, vibration, and electrical parameters to forecast potential core issues. This approach reduces unplanned downtime and optimizes maintenance costs.

Regular inspection, temperature monitoring, electrical testing, cleaning, vibration management, lubrication, and thorough documentation collectively ensure the long-term reliability of power distribution transformer cores. Implementing these maintenance practices enhances efficiency, reduces energy losses, and prevents unexpected downtime, ultimately extending the life of the transformer and safeguarding power distribution networks.

By following a structured maintenance plan, utilities and industrial operators can achieve consistent performance, lower operational costs, and ensure the safety and reliability of electrical infrastructure for years to come.

+86-523 8891 6699

+86-523 8891 6699  +86-523 8891 8266

+86-523 8891 8266  info@tl-core.com

info@tl-core.com  No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

English

English Español

Español Türk

Türk 中文简体

中文简体