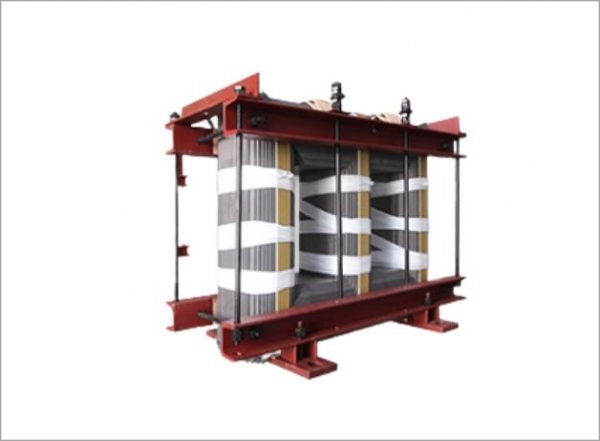

In dry-type transformers, the core serves as the central magnetic path that enables efficient power transfer between windings. Unlike oil-filled transformers, dry-type transformers rely on air or resin encapsulation for cooling, making the core’s quality even more vital for performance, energy efficiency, and operational safety. A well-designed core not only minimizes energy loss but also ensures temperature stability, mechanical strength, and reduced electromagnetic interference. Therefore, understanding the role and construction of the transformer core is key to achieving long-lasting, reliable electrical systems.

Transformer efficiency is largely determined by magnetic losses in the core, which include hysteresis and eddy current losses. The better the material quality and core construction, the lower these losses will be. Dry-type transformer cores typically use high-grade silicon steel or amorphous alloys designed to improve magnetic flux density and reduce heat generation. The core’s lamination structure and insulation coatings also play crucial roles in minimizing energy dissipation during magnetization cycles.

The core’s structural stability directly affects transformer safety. A low-quality or poorly assembled core can cause excessive vibration, noise, or localized overheating, leading to insulation damage and potential fire hazards. Since dry-type transformers are commonly used in indoor or confined environments such as commercial buildings, data centers, and hospitals, maintaining core integrity is critical for preventing operational failures and ensuring personnel safety.

Choosing the right material for a dry-type transformer core is a balance between efficiency, cost, and operating conditions. Below is a comparison of the most common core materials used in dry-type transformers:

| Core Material | Magnetic Losses | Temperature Rise | Durability | Application |

| Silicon Steel | Low | Moderate | High | General power distribution transformers |

| Amorphous Alloy | Very Low | Low | High | Energy-efficient and eco-friendly transformers |

| Ferrite Core | Moderate | Low | Medium | Small-scale or low-power transformers |

High manufacturing precision ensures that each lamination and joint in the transformer core aligns perfectly. This reduces magnetic flux leakage and improves energy conversion efficiency. Laser cutting and automated stacking are now commonly used to produce consistent, defect-free cores. Furthermore, vacuum annealing processes restore magnetic properties that may have been degraded during fabrication, significantly improving core performance.

Modern dry-type transformer cores are designed to maximize flux distribution while minimizing losses. The geometric arrangement—whether step-lap, mitered, or distributed gap design—significantly influences the overall energy efficiency. Step-lap core designs, for instance, create smoother magnetic transitions between laminations, reducing both losses and noise levels. These optimizations make dry-type transformers ideal for urban energy networks and green building systems that prioritize low carbon emissions and operational sustainability.

Investing in high-quality cores provides long-term cost advantages through reduced energy losses, lower maintenance costs, and extended equipment life. Additionally, improved efficiency translates into decreased carbon emissions, aligning with modern environmental regulations and energy conservation goals. In renewable energy and urban infrastructure applications, dry-type transformers with premium cores contribute significantly to achieving sustainable development objectives.

The quality of a dry-type transformer core is the cornerstone of its performance, safety, and longevity. From material selection to precision engineering, every aspect of core design determines the transformer's energy efficiency and operational stability. As industries demand higher reliability and greener solutions, investing in superior core materials and advanced manufacturing processes is no longer optional—it is essential for achieving both economic and environmental sustainability.

+86-523 8891 6699

+86-523 8891 6699  +86-523 8891 8266

+86-523 8891 8266  info@tl-core.com

info@tl-core.com  No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

English

English Español

Español Türk

Türk 中文简体

中文简体