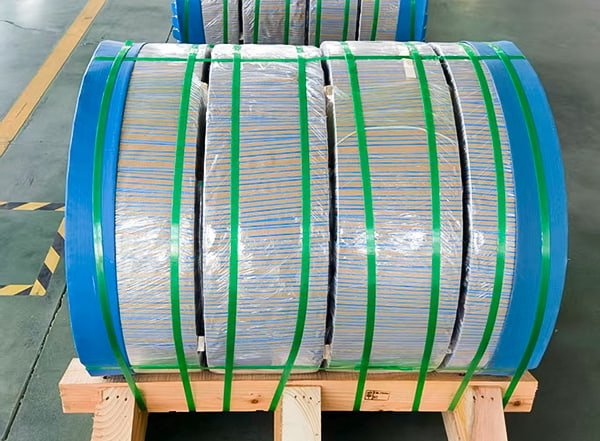

Silicon steel slitting coils are a critical raw material for the production of motors, transformers, generators, and other electromagnetic equipment. These coils are produced by slitting wide silicon steel master coils into narrow strips with precise widths and controlled edge quality. While the chemical composition and magnetic grade of silicon steel are essential, slitting quality plays an equally important role in determining the final performance of electrical components.

Poor slitting quality can introduce mechanical stress, edge damage, and dimensional inconsistency, all of which directly influence magnetic efficiency, energy losses, noise levels, and long-term reliability. Understanding how slitting quality affects silicon steel coils helps manufacturers optimize performance while reducing waste and operational costs.

Slitting quality refers to the overall precision and condition of silicon steel strips after the slitting process. It is determined by factors such as edge burr height, strip width tolerance, flatness, camber, surface integrity, and residual stress. Each of these parameters affects how the material behaves during lamination stacking and magnetic operation.

High-quality slitting ensures that the steel strips retain their designed magnetic properties while fitting perfectly into stator or transformer core assemblies. In contrast, inconsistent or rough slitting can degrade both manufacturing efficiency and end-product performance.

The magnetic performance of silicon steel coils is highly sensitive to mechanical damage caused during slitting. Poor slitting practices introduce localized stress along the strip edges, which disturbs the crystalline structure of the steel. This stress reduces magnetic permeability and increases core losses.

In applications such as transformers and high-efficiency motors, even small increases in core loss can significantly affect energy efficiency and operating temperature. Therefore, slitting quality directly influences compliance with energy efficiency standards.

Edge damage and stress concentration from poor slitting increase hysteresis loss and eddy current loss. Burrs can also create electrical bridges between laminations, reducing insulation effectiveness and further increasing losses. High-quality slitting minimizes these effects, preserving the designed magnetic characteristics of the steel.

Dimensional consistency is crucial when silicon steel slitting coils are stamped or laser-cut into laminations. Variations in strip width or camber can lead to misalignment during stacking, resulting in uneven air gaps and mechanical imbalance in rotating equipment.

High slitting accuracy ensures that laminations fit together tightly, improving magnetic flux continuity and mechanical stability. This is particularly important for high-speed motors and precision electrical equipment.

Poor slitting quality reduces the effective stacking factor due to burrs and uneven edges. A lower stacking factor means less active magnetic material per unit volume, which reduces output efficiency. Cleanly slit edges help achieve a higher stacking factor and better overall performance.

Noise and vibration in electrical equipment are often linked to magnetic imbalance and mechanical imperfections. Slitting defects can cause uneven magnetic forces, leading to audible hum, vibration, and premature wear of bearings and housings.

Additionally, increased core losses from poor slitting generate excess heat. Over time, higher operating temperatures accelerate insulation aging and reduce equipment lifespan.

Consistently slit silicon steel coils help maintain uniform magnetic flux distribution, which stabilizes operating temperature. This is especially important for transformers and motors designed for continuous duty cycles or high-load conditions.

| Aspect | High-Quality Slitting | Low-Quality Slitting |

| Edge Condition | Smooth, low burr | Rough, high burr |

| Magnetic Loss | Low and stable | Increased and unstable |

| Assembly Accuracy | High precision | Misalignment risk |

| Equipment Lifespan | Longer | Shortened |

Advanced slitting lines equipped with precision knives, automatic tension control, and burr monitoring systems are essential for producing high-quality silicon steel slitting coils. Proper knife material selection and regular maintenance prevent edge wear that can damage the steel.

Process control, including speed regulation and strip tension balance, also plays a vital role in minimizing residual stress and ensuring consistent strip geometry.

For OEMs and end users, investing in high-quality silicon steel slitting coils reduces downstream processing issues, scrap rates, and warranty claims. Better slitting quality translates into easier lamination punching, more consistent assembly, and predictable performance in final products.

In competitive markets where efficiency standards and durability expectations continue to rise, slitting quality is no longer a secondary concern but a core factor in product differentiation.

Slitting quality has a direct and measurable impact on the performance of silicon steel coils. From magnetic efficiency and thermal stability to noise reduction and equipment lifespan, every aspect of electrical performance is influenced by how well the steel is slit.

By prioritizing precision slitting processes and stringent quality control, manufacturers can unlock the full potential of silicon steel materials, ensuring reliable, efficient, and long-lasting electrical equipment.

+86-523 8891 6699

+86-523 8891 6699  +86-523 8891 8266

+86-523 8891 8266  info@tl-core.com

info@tl-core.com  No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

English

English Español

Español Türk

Türk 中文简体

中文简体