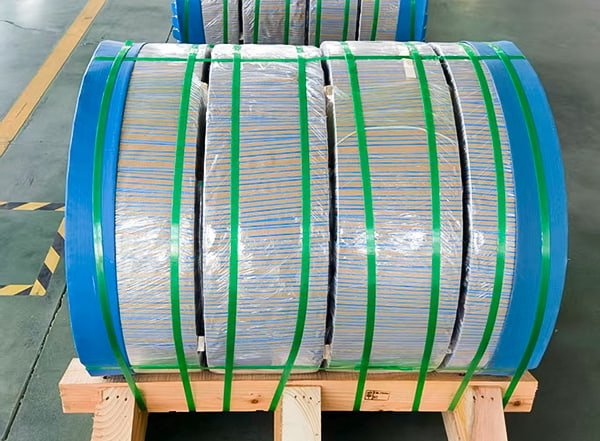

Silicon steel slitting coils are specialized steel products designed to enhance the performance of electrical devices. They are primarily used in the electrical industry due to their excellent magnetic properties, low core loss, and high permeability. Understanding their applications helps manufacturers select the right materials for transformers, motors, and generators.

Silicon steel slitting coils are known for several core properties that make them indispensable in electrical applications. These include high magnetic permeability, which allows efficient magnetic flux flow; low hysteresis and eddy current losses; and dimensional stability. Additionally, the slitting process enables precise widths suitable for winding and stacking in electrical cores.

The high magnetic permeability of silicon steel slitting coils ensures that magnetic flux passes easily through the material, reducing energy loss in transformers and motors. This property is critical for achieving high efficiency in electrical devices.

Core loss, which includes hysteresis and eddy current loss, is a primary factor affecting the efficiency of electrical equipment. Silicon steel slitting coils minimize these losses, which in turn improves performance and reduces operational costs.

Transformers are one of the most common applications of silicon steel slitting coils. The material is used to produce laminated cores, which help reduce energy loss and maintain efficiency under varying load conditions.

In distribution transformers, silicon steel slitting coils are used to construct thin laminated cores that allow for minimal energy dissipation. The slitting process ensures that the laminations have precise widths to optimize magnetic flux and reduce vibration and noise.

For large power transformers, silicon steel slitting coils provide the strength and magnetic properties necessary to handle high voltages and currents. Properly selected and slit coils help maintain core efficiency and thermal stability during heavy-duty operations.

Silicon steel slitting coils are also widely used in motor cores, where low core loss and high permeability contribute to motor efficiency, reduced heat generation, and longer operational life.

In induction motors, precise lamination from silicon steel slitting coils minimizes energy loss and improves torque output. The material's stability ensures consistent performance under various operating conditions.

Synchronous motors also benefit from the use of silicon steel slitting coils, particularly in reducing eddy current losses in stator and rotor cores. This allows for higher efficiency and lower operational noise.

Beyond transformers and motors, silicon steel slitting coils are utilized in generators, reactors, and magnetic sensors. Their precise magnetic properties ensure optimal energy conversion and minimal heat generation.

Generators require materials that maintain magnetic efficiency under continuous rotation. Silicon steel slitting coils reduce losses in the stator and rotor, contributing to stable voltage output and longer equipment life.

High-precision magnetic sensors in industrial and automotive applications often use silicon steel slitting coils. The material ensures accurate detection of magnetic flux changes with minimal signal distortion.

Selecting the right silicon steel slitting coils involves evaluating thickness, grade, surface coating, and cutting precision. These factors influence the performance of transformers, motors, and other electrical components.

Coil thickness affects core losses, while steel grade determines the magnetic properties. Choosing the correct combination is essential for specific electrical applications to optimize efficiency and reduce operational costs.

Insulating coatings on silicon steel slitting coils prevent short circuits between laminations and reduce eddy current losses. Selecting the appropriate coating is crucial for both efficiency and longevity.

Accurate slitting ensures uniform lamination width, which is vital for minimizing vibration, noise, and energy loss in electrical cores. High-precision slitting machines contribute significantly to overall product performance.

Silicon steel slitting coils play a pivotal role in the electrical industry, enhancing the efficiency and longevity of transformers, motors, generators, and other devices. Understanding their applications and selecting the right material specifications is crucial for optimizing performance and energy efficiency. From reducing core losses to ensuring magnetic stability, these coils remain a core component in modern electrical engineering.

+86-523 8891 6699

+86-523 8891 6699  +86-523 8891 8266

+86-523 8891 8266  info@tl-core.com

info@tl-core.com  No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

English

English Español

Español Türk

Türk 中文简体

中文简体