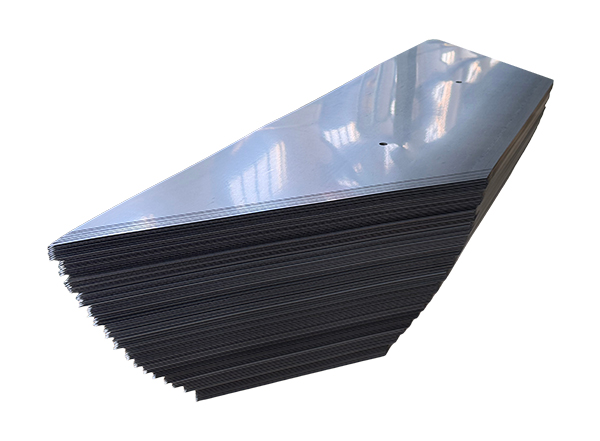

Transformer cut laminations are thin sheets of electrical steel or silicon steel stacked to form the magnetic core of a transformer. Their primary purpose is to reduce eddy current and hysteresis losses while providing a path for magnetic flux. The stacking factor, which represents the ratio of the total steel area to the overall core area including insulation gaps, significantly impacts transformer efficiency and magnetic flux density.

The stacking factor is calculated as the ratio of the total metal cross-sectional area to the gross cross-sectional area of the core. It accounts for the insulation between laminations, gaps, and any non-metallic spacing. Typical stacking factors for silicon steel laminations range from 0.85 to 0.96, depending on manufacturing precision and lamination thickness.

The formula for stacking factor is:

Transformer efficiency is influenced by core losses, including hysteresis and eddy current losses. Laminations are insulated to minimize eddy currents, but the stacking factor determines the proportion of steel to total core volume.

Magnetic flux density (B) is defined as the magnetic flux per unit cross-sectional area of the core. Stacking factor directly influences B because only the metal portion conducts flux, while air gaps reduce effective permeability.

Thinner laminations allow for higher stacking factors because insulation layers occupy less volume. However, very thin laminations are more difficult and expensive to manufacture.

Different core designs such as EI, EE, UI, and toroidal cores have varying achievable stacking factors due to geometry and insulation requirements.

| Core Type | Typical Stacking Factor | Impact on Efficiency | Impact on Flux Density |

| EI Laminations | 0.92–0.95 | High efficiency | Moderate flux density |

| EE Laminations | 0.88–0.93 | Moderate efficiency | Moderate flux density |

| UI Laminations | 0.85–0.90 | Lower efficiency | Lower flux density |

| Toroidal Laminations | 0.94–0.96 | Very high efficiency | High flux density |

The stacking factor is influenced by manufacturing precision, insulation coating, and assembly technique. Proper stacking alignment, high-quality insulation, and minimal burrs ensure optimal stacking factor and consistent transformer performance.

Transformer cut laminations stacking factor is a key determinant of transformer efficiency and magnetic flux density. Higher stacking factors improve core efficiency, reduce losses, and increase flux density, while lower stacking factors can reduce performance. By carefully selecting lamination thickness, core geometry, and assembly methods, transformer designers can optimize performance, reduce energy losses, and ensure long-term reliability.

+86-523 8891 6699

+86-523 8891 6699  +86-523 8891 8266

+86-523 8891 8266  info@tl-core.com

info@tl-core.com  No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

English

English Español

Español Türk

Türk 中文简体

中文简体