Transformer core is a critical component of a transformer, serving as the medium for magnetic flux, which is essential for voltage transformation. Made typically from laminated sheets of high-permeability silicon steel, the core minimizes energy losses due to eddy currents and hysteresis. The laminations, insulated from each other, reduce the formation of eddy currents, enhancing the transformer's efficiency. The core can be constructed in different shapes, primarily the shell type and core type. In a core-type transformer, the windings encircle the core, whereas in a shell-type transformer, the core encircles the windings. This distinction influences the transformer's performance and application. The core's design aims to provide a low reluctance path for the magnetic flux, thus ensuring minimal energy loss and efficient magnetic coupling between the primary and secondary windings. Furthermore, the core's material and design are crucial in determining the transformer's performance characteristics, including efficiency, capacity, and thermal stability. Advanced core materials like amorphous steel are sometimes used to further reduce losses. Proper core construction and material selection are essential for the reliable and efficient operation of transformers in power distribution and electrical equipment.

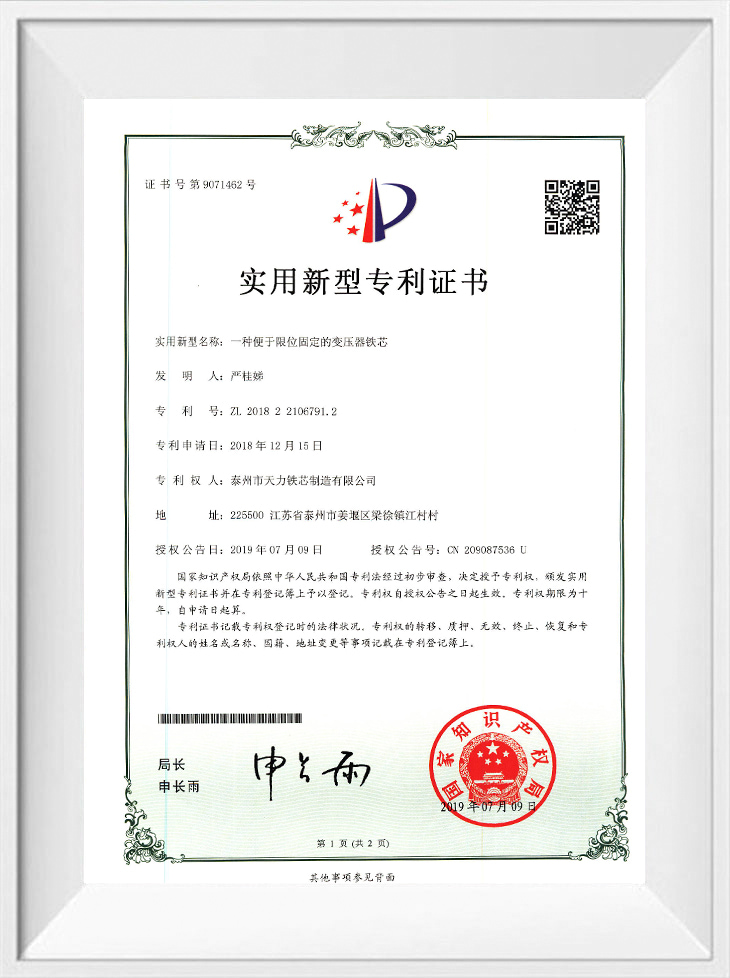

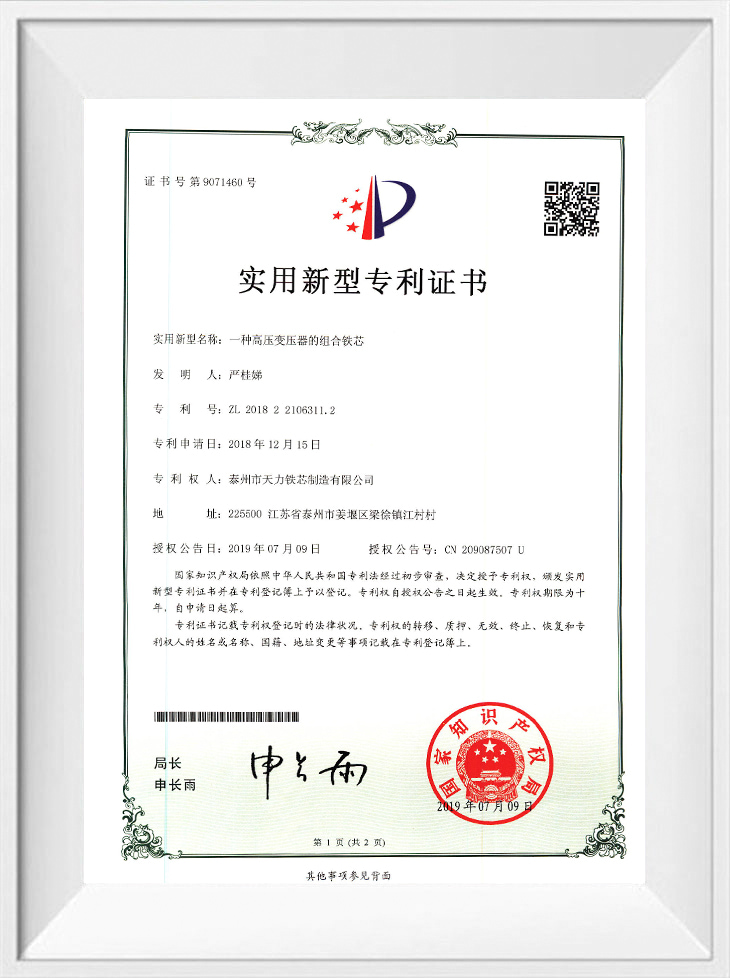

Taizhou Tianli Iron Core Manufacturing Co., Ltd. is China Main Transformer Core Suppliers and Electrical steel core factory. Established in 2009, Tianli Iron Core is a leading full-solution provider of transformer core materials and assemblies. We specialize in slitted coils, core laminations, and precision-assembled magnetic cores for distribution and power transformers. With a strong technical foundation and materials sourced from top-tier mills like Shougang and Baosteel, we deliver reliable, high-performance solutions tailored to each client’s needs. Our experienced team ensures quality, flexibility, and responsive service across global markets. From material selection to final core assembly, Tianli is committed to powering your success—efficiently and dependably.

Your trusted partner in transformer core excellence.

Understanding Oil-Immersed Transformer Fundamentals Oil-immersed transformers represent the backbone of electrical power distribution systems worldwide, serving critical roles in transmitting electricity from generation facilities to end users effici...

View MoreTransformer cores are the magnetic backbone of electrical transformers. They provide a low-reluctance path for magnetic flux, allowing efficient transfer of energy between primary and secondary windings. Without a properly designed core, a transforme...

View MoreSilicon steel slitting coils are essential components in the manufacturing and electrical industries, providing a high-performance material solution for transformers, motors, and other electrical devices. These coils are processed to achieve precise ...

View MoreTransformer core heat dissipation method

The transformer core handles heat dissipation during operation through several key mechanisms:

Core Material Properties:

Thermal Conductivity: The choice of core material impacts how effectively heat is conducted away from the core. High-quality silicon steel or advanced materials like amorphous steel typically have better thermal conductivity, which helps in distributing heat more evenly.

Insulation: Laminations in the core are usually coated with insulating materials that can withstand high temperatures and prevent thermal degradation.

Core Design:

Lamination Thickness and Configuration: The thickness and arrangement of core laminations can affect heat dissipation. Thin laminations reduce eddy current losses, which in turn reduces heat generation.

Ventilation and Cooling Channels: Some transformer designs incorporate ventilation or cooling channels to enhance airflow and improve heat dissipation.

Transformer Cooling Systems:

Oil Cooling: Many transformers use oil as both an insulator and a coolant. The oil circulates through the core and windings, absorbing and transferring heat to the outer parts of the transformer where it can be dissipated.

Air Cooling: In air-cooled transformers, fans or natural convection help dissipate heat from the surface of the transformer.

Heat Dissipation Mechanisms:

Radiation and Convection: The surface of the transformer core radiates heat into the surrounding environment. Convection currents, whether natural or forced by fans, help carry away the heat.

Heat Sinks: Some designs include heat sinks or additional cooling elements attached to the core to enhance heat dissipation.

Thermal Management Practices:

Monitoring Systems: Many modern transformers are equipped with thermal monitoring systems that track temperature and ensure that the core does not exceed safe operating limits.

Maintenance: Regular maintenance ensures that cooling systems, such as oil levels and cooling fans, are functioning properly, preventing overheating.

Effective heat dissipation is crucial for maintaining the core’s performance and longevity, as excessive heat can lead to reduced efficiency, potential damage, and increased risk of failure.