Oil-immersed transformer core is a critical component in power distribution systems, designed to efficiently transfer electrical energy between circuits through electromagnetic induction. This type of transformer utilizes a laminated steel core, which is constructed from thin, insulated steel sheets to minimize eddy current losses and enhance magnetic flux flow. The core is typically made from high-grade silicon steel, known for its magnetic properties, ensuring high efficiency and low energy loss during operation. The core is immersed in a tank filled with insulating oil, which serves multiple purposes. Primarily, the oil acts as a coolant, dissipating heat generated during the transformation process, thereby preventing overheating and extending the transformer's lifespan. Additionally, the oil provides electrical insulation, safeguarding the core and windings from potential short circuits. The oil also enhances the mechanical strength of the windings, protecting them from physical stresses caused by thermal expansion and contraction. The design of the oil-immersed transformer core is optimized for minimal noise and vibration, featuring tight lamination and precise assembly techniques. This design not only improves operational efficiency but also reduces environmental impact and maintenance requirements. Overall, the oil-immersed transformer core is a robust and reliable component, essential for stable and efficient power transmission in various industrial and commercial applications.

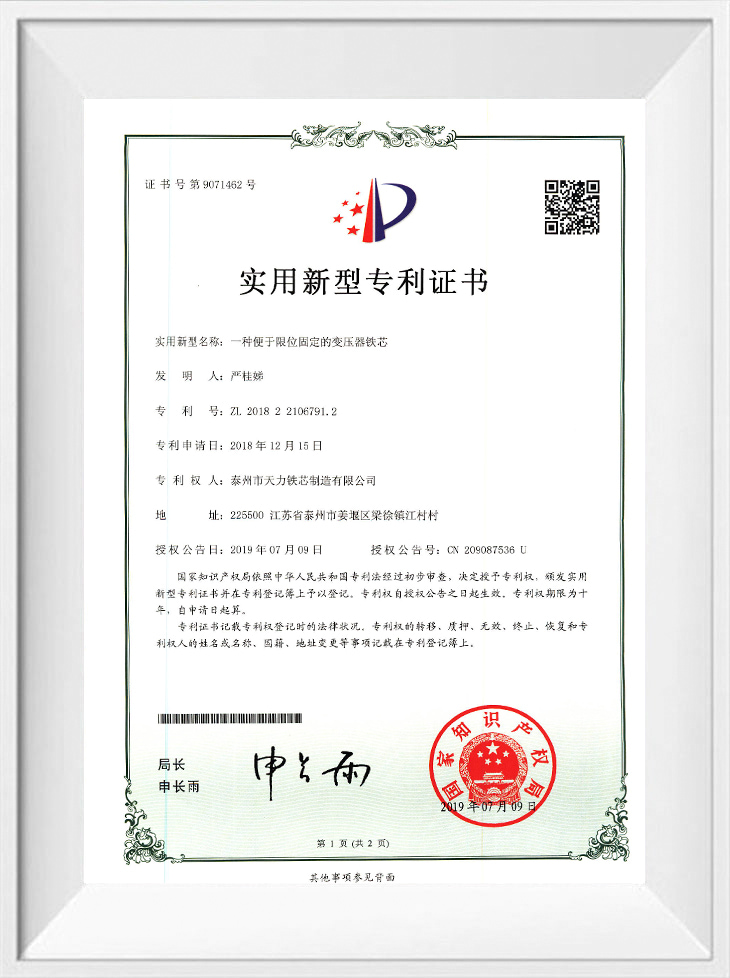

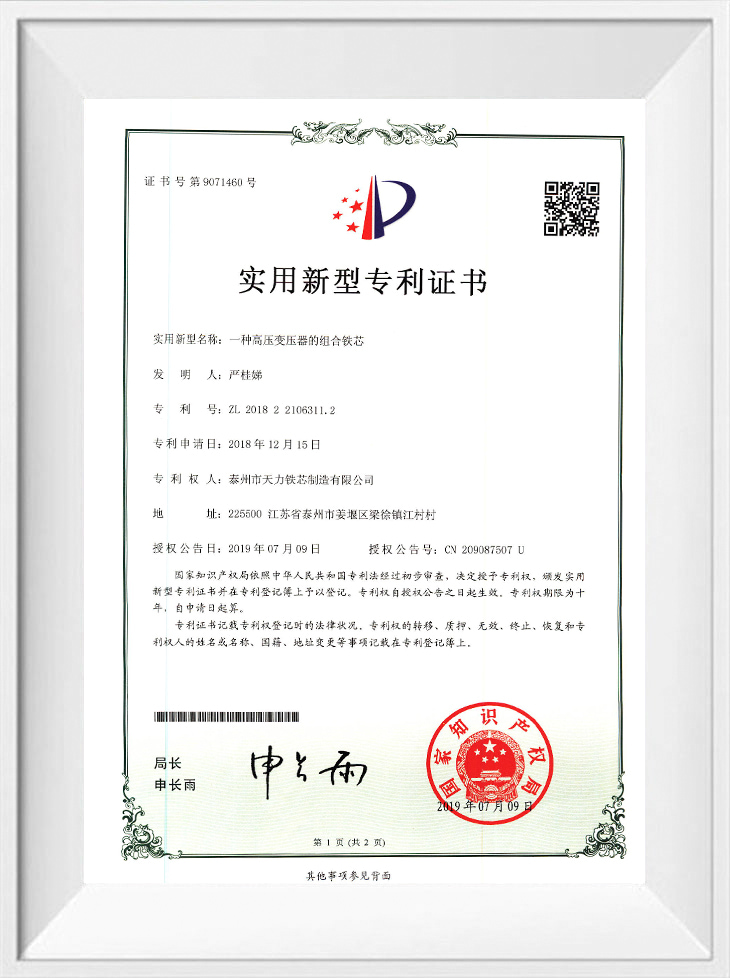

Taizhou Tianli Iron Core Manufacturing Co., Ltd. is China Oil-Immersed Transformer Core manufacturers and OEM/ODM Oil-Immersed Transformer Core company. Established in 2009, Tianli Iron Core is a leading full-solution provider of transformer core materials and assemblies. We specialize in slitted coils, core laminations, and precision-assembled magnetic cores for distribution and power transformers. With a strong technical foundation and materials sourced from top-tier mills like Shougang and Baosteel, we deliver reliable, high-performance solutions tailored to each client’s needs. Our experienced team ensures quality, flexibility, and responsive service across global markets. From material selection to final core assembly, Tianli is committed to powering your success—efficiently and dependably.

Your trusted partner in transformer core excellence.

Understanding Oil-Immersed Transformer Fundamentals Oil-immersed transformers represent the backbone of electrical power distribution systems worldwid...

View MoreTransformer cores are the magnetic backbone of electrical transformers. They provide a low-reluctance path for magnetic flux, allowing efficient trans...

View MoreSilicon steel slitting coils are essential components in the manufacturing and electrical industries, providing a high-performance material solution f...

View MoreSilicon steel slitting coils are narrow-width coils produced by slitting wide silicon steel master coils into precise strip widths. Silicon steel, als...

View MoreOil-immersed transformer cores are a critical component in power distribution and transmission systems. These cores are submerged in insulating oil th...

View MoreEfficiency rating of oil-Immersed transformer core and its performance under various load conditions

The efficiency rating of an oil-immersed transformer core typically ranges from 98% to 99.7%, depending on its design, materials used (such as high-grade silicon steel), and manufacturing quality. The core's efficiency is influenced by factors like core losses (hysteresis and eddy current losses) and load losses (resistance in the windings).

Performance Under Various Load Conditions:

Under Light Load:

At low loads, the transformer core still incurs no-load losses, which include core losses such as hysteresis and eddy currents. While these losses are minimal due to the high-quality laminated steel used in the core, they remain constant regardless of the load.

The efficiency tends to be lower under light load conditions because a significant portion of the total losses comes from no-load losses.

At Full Load:

At or near full load, the transformer operates more efficiently as the load losses (due to winding resistance) become more proportional to the load being transferred.

High-grade materials and precise lamination techniques help minimize the magnetic flux leakage, ensuring high efficiency at full load. Most oil-immersed transformer cores perform optimally at or near full capacity, maximizing energy transfer with minimal losses.

Overload Conditions:

In short-term overload situations, the transformer core may handle additional loads without significant efficiency loss, but the insulating oil plays a key role in dissipating the excess heat. Long-term overloads, however, can lead to thermal degradation, reducing efficiency and potentially damaging the core.

Key Efficiency Factors:

Core Material: The use of high-grade silicon steel with low magnetic coercivity improves the magnetic efficiency and reduces energy loss.

Lamination: Thin, tightly laminated sheets reduce eddy currents, which helps maintain high efficiency under various load conditions.

Insulating Oil: Efficient cooling and insulation provided by the oil help maintain optimal performance by preventing overheating and maintaining electrical insulation.

Oil-immersed transformer core is designed to maintain high efficiency across a wide range of load conditions, though they are most efficient when operating closer to full load.